Tufts MAKE

In four short years the product design club I helped start at Tufts went from de-creaming Oreos in a basement to helping hundreds of students learn new skills through interdisciplinary projects, workshops, and weekend-long events.

Through Tufts MAKE my team and I taught ourselves about the product design process long before our school expected us to, paving the way for summer internships, the growth of the undergraduate Human Factors program, and eventually a full graduate scholarship to build the Maker Network.

Tufts MAKE is the proudest accomplishment of my Tufts career, and I'm so glad to see that students now have the opportunities to "learn by making" that we could only dream of when the club started.

The Problem

In the Fall of 2012 I attended the International Human Factors and Ergonomics Society's 56th Annual Meeting as a newly-decided Human Factors major. I sat in on a session that described a mismatch between employers' expectations of new Human Factors employees and the skills those employees had after completing school.

These quotes in particular stood out to me (emphasis mine):

Educational needs of new Human Factors professionals:

A major deficit in the educational experience of HF/E professionals is the understanding of the processes used in the ‘hard’ engineering disciplines.

The respondents clearly saw a need to be effective team members in multidisciplinary settings...

Employers' expectations of new Human Factors professionals:

Application of the knowledge gained in college to practical design tasks was reported lacking in the new professionals’ skill set...

Skills to effectively interact in multi-disciplinary and cross-functional teams were [also] found wanting...

During the Q&A, two Google hiring managers remarked that their experience reflected the survey data, and said:

Students are often competent in some areas, but completely incompetent when it comes to designing things and working together on projects....

When all I see are theoretical HF/E courses on a resume it’s almost not even worth looking at. We look for hands-on design work and projects that prove you’re good at something.

My first thought?

"Uh Oh..."

Hearing that even my school's Human Factors program wouldn't fully prepare me to work in the field was concerning, but not entirely unexpected. I had noticed a dearth of "applied" design opportunities in my future courses, but the session's emphasis on "multi-disciplinary and cross-functional" teamwork helped me realize that I needed to take my education into my own hands if I wanted to get that kind of experience.

My first thought was to start an interdisciplinary product design club of some kind, but I had no idea how to go about starting one, who to collaborate with, how to attract members, where meetings could be held, or how to actually practice product design.

I mentioned the idea of starting a club to my advisor Dan Hannon, and after finding a few other interested students we started working on our prospective club's very first project: the Oreo De-Creamer.

Starting a club

De-creaming an Oreo provided us with an opportunity to practice a realistic product design process long before our Human Factors program required, and helped at least one team member land an internship the following summer. The difficulties we encountered in trying to gain access to tools, money, and materials also revealed the need for a club such as ours to exist. By forming a product design and making-oriented club, we could hopefully generate grassroots interest for greater access to the tools and resources that would enable us to teach ourselves new skills. At a time when even Tufts' long-running Robotics Club was feeling squeezed, trying to shift Tufts' culture to be more maker-friendly felt idealistic even to me.

Unsure of whether starting such a club would be "allowed" by Tufts and wary of starting something as big as InvenTech again, I asked my advisor Dan Hannon for advice. He responded with a quote often attributed to Grace Hopper:

It's easier to ask for forgiveness than it is to get permission.

He encouraged me to continue doing what I was doing, use common sense, and push the boundaries of making at Tufts. He suspected that Tufts' Mechanical Engineering department would be at least somewhat receptive to the idea, and even helped us set up a meeting with the department's head.

With his support and the prospect of a campus-wide "makerspace" floating in my head, 4 members of the Oreo De-Creamer team reunited to start a new club in the Fall of 2013.

We called it Tufts MAKE and wrote the following into our club's constitution:

Tufts MAKE is an interdisciplinary, team-based design group that explores the world of product design by making things. Its primary objective/purpose is to help Tufts students make what they want to make, and hopefully gain a broad, interdisciplinary perspective of product design along the way.

As an organization, Tufts MAKE seeks to provide the opportunities and resources for Tufts students to have first-hand experience working on digital or physical products using real-world design methodologies. By organizing workshops, speakers, lessons, and field trips open to the entire Tufts community, MAKE intends to serve as a major STEAM proponent on campus and encourage greater collaboration between the schools of Liberal Arts and Engineering.

Another founding member and I designed flyers to post around campus, and our group met with roughly 30 interested students on the lawn in front of Bray Lab to discuss potential project ideas. The club was in motion.

Reviving another club

The official process of starting a new club at Tufts turned out to be almost as convoluted and paperwork-heavy as starting a new business.

Citing space constraints, Tufts' Office for Campus Life (OCL) was very reluctant to approve of brand new clubs that could potentially use up space and resources. Because our club was so new and unproven, the council was keen on categorizing us as a "sub-group" of a parent club called the Tufts Human Factors & Ergonomics Society (THFES), which was similarly interested in product design from a professional development perspective.

The problem was that THFES had failed to renew their club membership in the year prior, requiring even more paperwork and re-recognition from the national HFES. I coordinated this effort, inviting students from my class to join THFES' leadership and collaborating with them to meet the OCL's requirements and plan Human Factors-related events.

Eventually both clubs were officially recognized by Tufts, enabling THFES and Tufts MAKE to reserve space and advertise themselves on campus.

Cardboard sled-making

One student who attended Tufts MAKE's first meeting noticed that the plastic bins that Tufts students used as makeshift sleds would often leave behind sharp bits of plastic that had to be cleaned up in the spring. We decided to try to make a safer and less wasteful alternative using large cardboard boxes from Tufts' dining halls and garbage bags.

During our first meeting we realized that setting up "Make Your Own Sled" stations at the top of each hill could be a unique and memorable marketing avenue for Tufts MAKE. With that in mind, we agreed to optimize the design of our sleds for the following:

- Time to assemble

- Folding complexity

- Amount of tape & bags required (our cost)

- Structural integrity

We created 5 different prototypes and tested them on Tufts' best sledding hill near the intersection of College and Boston Ave. Most of them weren't long enough to allow for even weight distribution, preventing them from working very well at all. The most complex toboggan-esque design worked just as well as most sleds, but only lasted 4 trips before rocks and sticks tore through its front. It likely would have lasted longer if the hill's snow quality had been better, but we never got to test a second iteration due to warming weather.

Phone projector

Another attendee of Tufts MAKE's first meeting had always wanted to make her own inexpensive, portable projector. We knew that making a consumer-quality device wasn't feasible with our resources, but thinking through different approaches was a good enough reason to practice doing another small-scale product design sprint.

During our first meeting we broke out some sticky notes and considered possible approaches for phone insertion, lens adjustment, image adjustment, media controls, and phone ejection. We then looked online for additional ideas before picking a few approaches from each category and ordering some basic parts like a variety of fresnel lenses.

We cut a hole through a shoebox, positioned our lens, sealed the border with black eletrical tape, and made a makeshift stand out of paperclips to hold an iPhone 4 perpendicular to the lens.

The image our very basic prototype produced was very difficult to see even in a pitch-black closet. After experimenting with different lenses and fiddling with distances, we concluded that the backlight of our smartphones simply weren't bright enough to project a decent image at an appreciable size. We considered creating a second prototype with a high-res LCD and external light source, but with holidays and final exams approaching we decided to end the project.

Growing the club

During our club's second kickoff meeting in the Spring of 2014, students were a bit unsure about Tufts MAKE's exclusively project-based format. Citing a general lack of time, they were more interested in standalone workshops that taught new skills than multi-week projects. We decided to adjust the club's format to focus on one larger project each semester and offer self-contained workshops whenever possible.

Tufts Dash

Students who were interested in learning how to make apps and design for mobile devices attended a separate interest meeting for what would eventually become Tufts Dash; a centralized dashboard for all of Tufts' real-time information.

This project was particularly important for Tufts MAKE because it was the first time that our students worked and collaborated across disciplines. Some students were more interested in Dash's code and web technologies while others used it as an opportunity to learn Sketch and think through its interface design.

Workshops and events

Between 2013 and 2015 we held nearly 30 workshops and events. Here are a few:

- User interface design (and prototyping) with Sketch for Mac

- Design thinking and sketching

- The basics of crochet

- The basics of soldering

- CAD basics with OnShape

- Raspberry Pi 2

forwith dummies - Make your own website/portfolio with WordPress

- Making a website: the basics of HTML & CSS (and WordPress)

I coordinated each of these events and led our workshops on WordPress, website basics, Sketch for Mac, and user interface prototyping. I also wrote our bi-weekly newsletter, created a website at tuftsmake.com to advertise our upcoming sessions, and organized field trips to the U.S. Department of Transportation's Volpe Center and the Design Exchange Boston Summit.

Making connections

Tufts Daily, November 18th, 2013. Please note that all four of us were co-founders.

After a few months of campus-wide advertising and coverage in the Tufts Daily, Brian Gravel from the Tufts Center for Engineering Education and Outreach (CEEO) reached out to learn more about our group and told us about a small makerspace pilot they were conducting in the summer. Eager to contribute toward an eventual campus-wide makerspace, I helped the CEEO with their summer pilot and met Chris Rogers, who would eventually become the department chair of Mechanical Engineering and my graduate advisor.

At the CEEO I also met a number of graduate students who were interested in furthering student education through making; some of whom were developing new in-makerspace technologies that I found particularly interesting. By the end of the makerspace's summer pilot I had decided to join the CEEO as an incoming graduate student myself.

The CEEO also pointed me toward the Tufts Crafts Center and the efforts of undergraduate Nic Lusardo to rejuvenate their student-run space. I also met the undergraduate leaders of the Tufts Robotics Club and the Entrepreneurial Leadership Club who were also interested in collaborating to promote making at Tufts.

Establishing the club

In 2015 (my senior year) the CEEO and Mechanical Engineering departments opened their first dedicated makerspace named Jumbo's Maker Studio, providing every Tufts student with far more tools and capabilities than our founding group had access to when building the Oreo De-Creamer just two years prior.

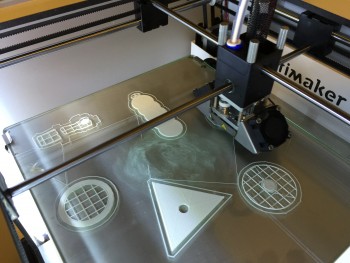

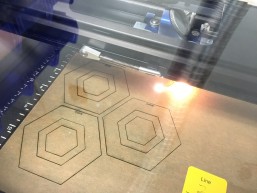

We continued to hold workshops and offer new ones on 3D printing, laser-cutting, electronics, and even started a weekly "waffle night" that brought new makers into Tufts' space.

By the time my co-founders and I graduated in early 2015, Tufts MAKE had over 300 students on its mailing list and had succeeded in contributing toward Tufts' new, more maker-friendly culture. Our group's promotion of the Human Factors major even convinced new students to join our department.

My graduate school career was just beginning, however, and I came up with an idea to celebrate our new spaces and partnerships with something big.

Soon after entering graduate school, I came up with an idea to celebrate our new spaces and partnerships with something we had never done before.

The Weekend of Making

To kick off the Spring of 2016 I led a massive collaborative event between Tufts MAKE, THFES, Tufts Robotics, Tufts Entrepreneurship Society, Tufts Crafts Center, and Jumbo's Maker Studio. Tufts' Mechanical Engineering department and the CEEO sponsored the event, and I worked with the leaders of each group to schedule 18 multi-disciplinary workshops into two days. We dubbed our new collective group the "Maker Network" and intended to use the event to showcase our spaces, clubs, activities, and share our "learning by making" philosophy.

Over 150 students attended our workshops on everything from screen-printing t-shirts to Arduino robotics. The weekend was also covered by the Tufts Daily, further increasing awareness of Tufts' new makerspaces across all of its campuses and growing our mailing list to over 500 subscribers. My advisor Chris Rogers told the Daily:

“Everyone was totally psyched,” Rogers said. “I was totally psyched to see the number of students, the diversity of students — they weren’t just engineers — and the fact that it was student-driven.”

Baby BB-8

Following the Weekend of Making's success, I led one last project before graduating: making a functional Baby BB-8. The knowledge of multiple disciplines and prototyping techniques that this project required made it another perfect opportunity for students to learn through prototyping, and it was a particularly fun project to finish my Tufts making career.

My takeaways

The willingness to try

Looking back on Tufts MAKE's accomplishments and history, I'm still surprised by how much good resulted from the simple act of showing up to build our silly little Oreo De-Creamer. The willingness of my co-founders to pursue a product design club ended up helping at least one member land an internship, exposed many hundreds of students to new skills and perspectives, and helped me identify the barriers that would eventually lead to the creation of the Maker Network and the full scholarship that enabled me to pursue a graduate education at Tufts.

There were of course a few discouraging nights where nobody showed up for our workshops or projects hit roadblocks, but they're greatly outweighed by the memories of students thanking us for our sessions, laughing at our BB-8 wobble across the floor, and excitedly trying new things in Tufts' makerspaces.

My desire to help and teach

During the many projects and workshops I led through Tufts MAKE, I came to realize that the locus of my motivation lies in the success of others, and especially my team. My work was always in service of "raising the tide" to benefit every kind of maker at Tufts - perfectly exemplified by the Weekend of Making.

Sharing my excitement about the web, Human Factors, and prototyping with other students through our projects and workshops never felt like work; it felt like fun.

Learning by making

Without exaggeration I believe that over half of the practical knowledge that I gained at Tufts was the direct result of Tufts MAKE and my own extracurricular efforts. Taking my education into my own hands by creating an outlet for putting theory into practice greatly improved my education and helped many other students as well.

Through Tufts MAKE I strengthened my:

- Technical skills

- HTML/CSS/JS, WordPress, Sketch, Axure, Pixate, Pixelmator

- CAD modeling, 3D printing, laser-cutting, SketchUp, Onshape

- Linux / Raspberry Pi, Python basics, soldering

- iOS (Xcode) and webapp development

- Soft skills

- Presenting & public speaking

- Product design approaches

- Team leadership

- Marketing (newsletters, flyers, strategies)

- Writing & communications

- Event planning

- Interdisciplinary skills

- Making a case for Human Factors and the design process

- Understanding, learning from, and balancing other perspectives

- Coordinating skills, interests, and work to be done

Passing the torch

The most difficult part of building Tufts MAKE was eventually having to let it go.

The cyclical 4-year nature of college has plenty of upsides, but the constant turnover of student leadership makes it particularly difficult for clubs to maintain their momentum. The perfect collaborative conditions that led to the Weekend of Making, for example, hasn't been replicated since. The creation of the Maker Network as an external, all-compassing hub for making at Tufts was intended to be a solution to the longevity problem, but technology can't replace the many highly-motivated students it takes for clubs to thrive and grow.

With that said, I couldn't be prouder of our little club's contribution to Tufts' maker culture. The spaces and resources that we wished for back in 2013 are now available to every Tufts student, institutionalizing the opportunity to "learn by making" that Tufts MAKE had pushed for since the beginning. The Human Factors program has more than quadrupled in size with students who are interested in product design, and a new interdisciplinary makerspace is on the horizon.

The school-wide cultural shift that our club dreamed of is now its lasting legacy.